Why Choose Offset Printing?

Offset Printing is preferred due to its mass-productive capability, which allows commercial clients to print in bulk whilst our modern-day digital printer is more suited for low quantity production. Over the years, digital print providers have grown their technological capabilities in pursuit for the needs of the market. Yet, the benefits and advantages of using offset printing is irreplaceable.

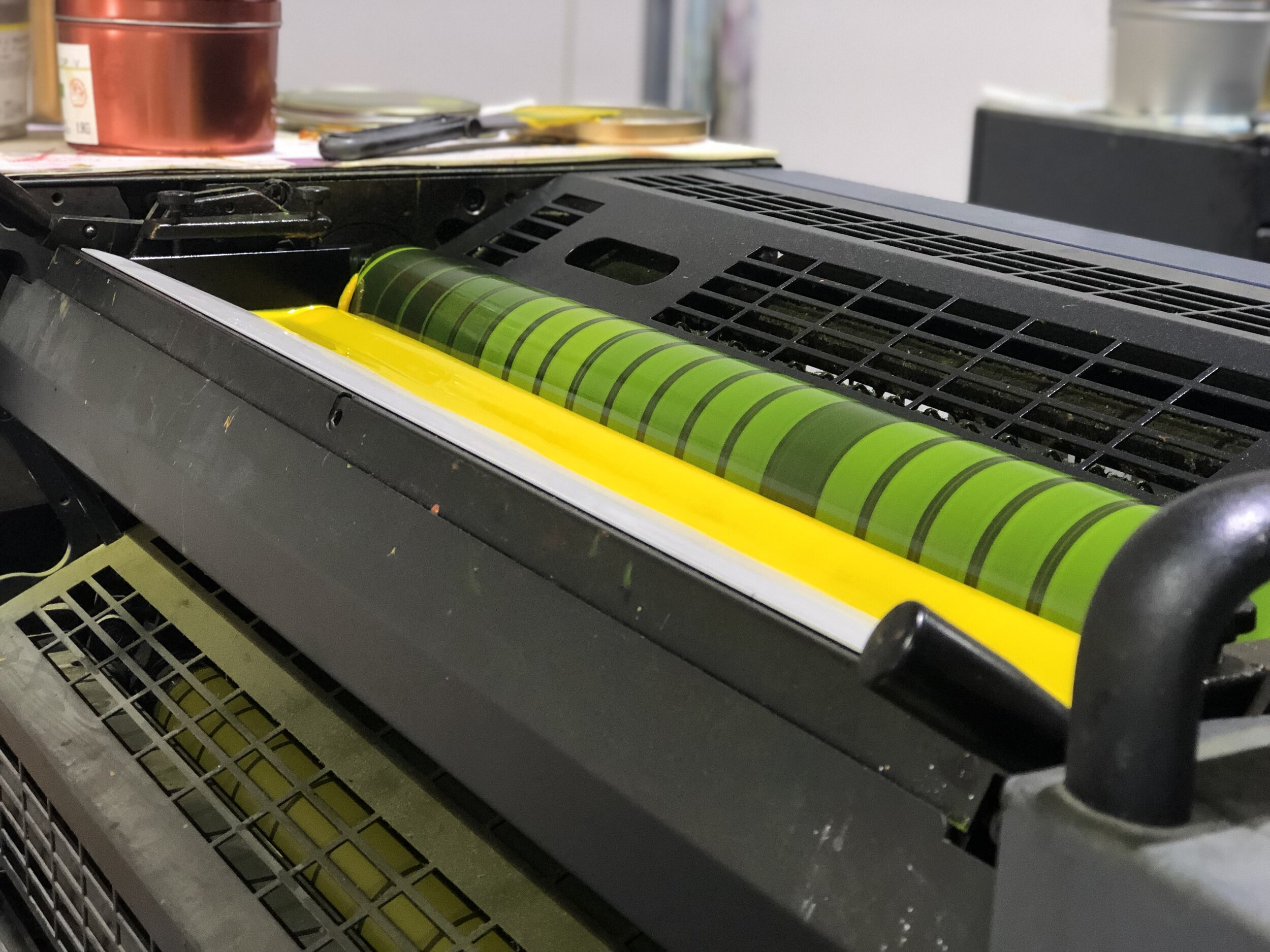

Fig 1. Yellow Component of a Heidelberg Four-Colour Offset Printing Machine

What is Offset Printing?

Offset Printing is a traditional lithography method that has evolved and developed for the industry. From a 1-colour machine, it has grown extensively to provide the basic CMYK or more.

To understand offset printing, we first need to look at a stage leading to offset printing – which is what we often call the ‘Prepress’ stage.

Pre-press, the preceding stage of offset printing is a process where an artwork/design will be transferred (via film negatives to printing plates during the early stages of printing) to printing plates via computer to plate (CTP) technology, which we will be sharing at a later stage in detail. Each print is generally separated into four components - CMYK, where the plates are separated into these four colours respectively for print.

In Offset Printing, the image will be transferred from the printing plate onto a rubber sheet, which is then used to roll onto a sheet of paper, vinyl or other surfaces. And that is how we get the word “offset.”

Fig 2. the image on the metal plate (white) at the top is being pressed onto the rubber (blue) below it before rolling onto the paper/vinyl surface.

WHY OFFSET PRINTING IS STILL A PREFERRED CHOICE TODAY?

For prints with quantities of 500 and above, offset printing is the go-to printing method. As the machine processes the image onto paper, it allows ongoing and high volume of prints unlike digital printing. On the other hand, it takes time for the process to occur. However, it is a more affordable option to adopt offset printing.

Secondly, the most important feature of offset printing is its high quality.

This process of “offsetting” the image and printing onto paper via pressing the image from printing plates onto the rubber and onto the paper results in an effective imprint where it gives the print a more lasting quality. Hence, offset printing is highly regarded for its high print quality and colour accuracy, which sometimes is also largely dependant on the skill of a technician operating the machine.

To find out more, speak to our team via email: contact@octogrampress.com or give us a call at +65 62708182